Cascade Power

This highly efficient 900 MW Siemens Energy single-shaft CCGT power plant supports decarbonisation by reducing carbon emissions in energy production by 5% in Alberta, Canada.

The Cascade Power project developed by Kineticor Resource and partners is the largest combined-cycle gas turbine (CCGT) power plant in Alberta Canada. It will emit approx. 62% less CO2 equivalent per MWh compared to a coal-fired generation plant and help the Canadian province to move towards clean electricity generation. Once operational, the power plant is expected to reduce Alberta’s carbon emissions from energy production by up to five percent.

“It is imperative that Alberta continue to have sufficient dispatchable generation to serve load during peak demand periods when other forms of generation are not able to contribute in a meaningful way.” Diane Kossman, Alberta Electrical System Operator (AESO)

With an estimated useful life of 30 years, the Cascade Power plant is expected to generate enough electricity to power up to 900,000 homes annually, accounting for approx. 8% of Alberta’s average electricity demand.

Cascade Power was also the first project to receive funding through the AIOC, the provincial corporation established in 2020 to provide loan guarantees for Indigenous groups seeking partnerships in major development projects.

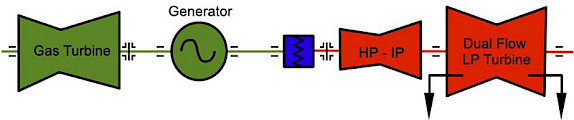

The power plant includes two Siemens Energy SGT6-8000H gas turbines each connected to a generator and a steam turbine with a size 320T SSS Clutch. Each single-shaft CCGT unit will deliver 450 MW at 3600 rpm of combined power from the gas turbine and the steam turbine. The units also incorporate a heat recovery steam generator (HRSG) to recover waste heat from the gas turbine and deliver steam to the steam turbine.

The 320T SSS Clutch rated at 275 MW, allows the gas turbine to start independently of the steam turbine and to engage automatically once gas turbine generates enough steam through the HRSG and the speed of the steam turbine matches the rotational speed of the generator. There are independent turning gears on both the gas turbine and steam turbines.

The single-shaft arrangement with an SSS Clutch provides greater flexibility and redundancy when compared to a multi-shaft arrangement where 2 gas turbines feed into one larger steam turbine.