Hinkley Point C

SSS supplies Pinion Turning Gear Clutches for the world’s largest steam turbines at the EDF Hinkley Point C Nuclear site in the UK.

Once completed, Hinkley Point C will produce up to 3.26GW of zero carbon power for 60 years from its two Framatome pressurised water reactors through the world’s largest steam turbines. This is enough power to supply approx. 6 million homes and it avoids 9 million tonnes of CO2 per year going into the atmosphere.

Each Arabelle steam turbine, will be capable of producing 1770 MW of power and the last stage will use a 75 inch blade which is the longest ever made and designed to optimise backpressure and efficiency.

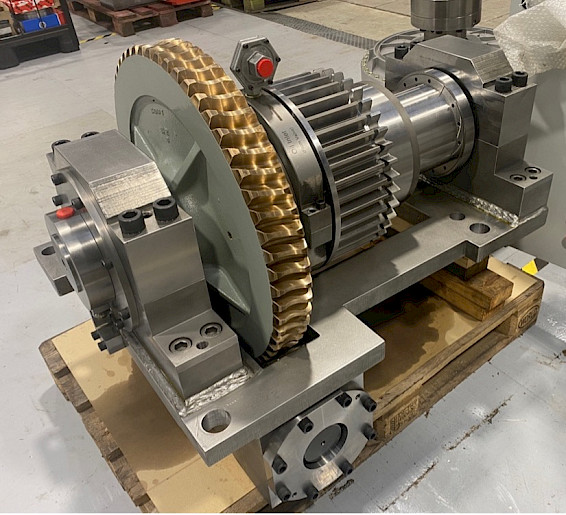

When the steam turbines are in the rundown cooling phase, the turbine needs to be kept turning to avoid distortion to the rotor. The pinion turning gear rotates the shaft-line at about 8 rpm and is driven by a 75kW motor, which engages through the SSS Clutch and pinion gear to keep the rotor shaft turning.The SSS Clutch automatically engages and disengages the pinion turning gear on its helical splines as required.

This is a special SSS Clutch that does not have a mechanical phasing mechanism. Instead, an SSS electronic monitoring and control system senses when the speeds of the steam turbine and pinion gear match before energising a solenoid valve to slide the pinion gear into mesh with the steam turbine using oil pressure. The control system is accurate enough to engage the clutch with minimal wear, ensuring the equipment lasts the life of the plant.

The SSS Clutch is easy to install and in the event the unit fails, the main gear wheel will not be damaged.

SSS Clutches have been used on turning gear systems for over 60 years and there are many nuclear sites globally using SSS Pinion Turning Gears of this design.