Rheinberg

This 54 MW TwinPac gas turbine CHP application at Solvay`s Rheinberg chemical plant provides efficient heat and electrical power and can operate as a synchronous condenser to support local grid stability

Solvay’s Rheinberg plant in Germany produces a number of energy intensive chemicals including soda ash, chlorine and polyvinylchloride. The energy costs for the plant are high, with a large demand for both electrical power and process steam. To increase capacity, reduce emissions and boost efficiency, the plant’s management decided to install a new combined heat and power (CHP) gas turbine plant to take over the supply of electrical baseload and process heat.

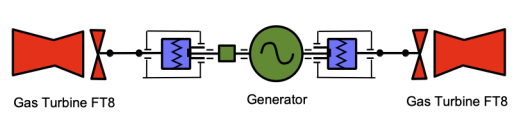

The 54 MW plant comprises 2 x FT8 aeroderivative gas turbines each rated at 27 MW in a “Twin-Pac” arrangement. Each gas turbine has a seperate power turbine which is connected to the synchronous generator via a flexible coupling and an Encased 170T SSS Clutch. The power turbines also feed Heat Recovery Steam Generators (HRSG) that have replaced an old steam boiler and provide the manufacturing plant with its production steam requirements.

The aeroderivative gas turbine design is particularly well suited to this system arrangement, as they have their own starter system to bring each gas turbine up to speed. The SSS Clutch engages when the speed of the gas turbine matches the speed to the generator and the teeth on the input shaft are automatically aligned to the teeth on the output shaft.

This CHP system design was driven by availability and part load efficiency requirements. The SSS Clutches at each end of the generator permit the gas turbines to operate independently, thus providing maximum flexibility and efficiency over a wide load range working conditions, between full load (54 MW) and half load (27 MW). If the power requirements drop below half load, one of the gas turbines can be shut down, providing a fundamental advantage over other gas turbines in the 50 MW power class.

A full redundancy concept was implemented at the Solvay plant, with separate auxiliaries, ancillaries and control systems provided for each gas turbine and HRSG. As such, either gas turbine or HRSG can be shut down for maintenance or repair work while the second unit remains operational.

The system can also function as a synchronous condenser. In this operating mode, the generator is uncoupled from the drivers and provides reactive power and inertia to the electricity grid with minimal mechanical losses.

The SSS 170T Clutches at the Rheinberg plant are seated in their own casings, which are mounted to the generator base frame. They are fed with oil from the generator oil system.