Nuclear Power

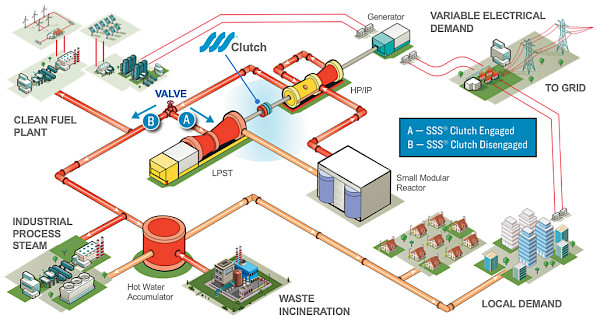

Traditionally, nuclear power plants have been large output units providing continuous base load electrical power, but the need to decarbonise the energy market is driving innovation into Small Modular Reactors (SMR) which will support wider applications like hot water and steam for industrial process applications and district heating. As the demand for power and heat can vary dramatically through the day or year, the SSS Clutch enables the Low-Pressure (LP) section of the steam turbine to easily switch between electrical generation mode and supplying heat and steam. This concept has been used widely in Combined Heat and Power (CHP) applications for other steam power plants, and is more flexible and efficient than steam extraction, as it allows complete diversion of the steam avoiding significant losses such as cooling flows.

The flexibilty of the steam turbine allows the reactor to operate at a continuous output, whilst the secondary island can switch between different operating modes. CHP systems can offer heat and steam for district heating, hot water accumulators or for many industrial processes including: steam electrolysis for hydrogen production or sea water desalination.

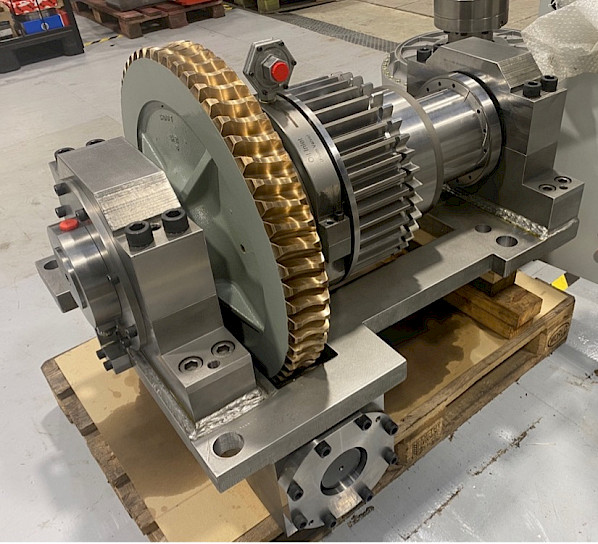

Nuclear Turning Gear Clutches

SSS has been supplying turning gear clutches to the nuclear industry since the 1960’s and has a wide reference list across many sites in Europe and Asia including Hinkley Point C, which is currently under construction in the UK. We have supplied both in-line units which drive through the steam turbine shaft end, and Pinion Turning Gear units which engage through a drive gear wheel and a parallel mounted pinion gear which is engaged using an SSS Clutch. The SSS Nuclear Pinion Turning Gear clutch provides a fail-safe mechanism to rotate the large steam turbine shaft during the cool down phase to prevent distortion.